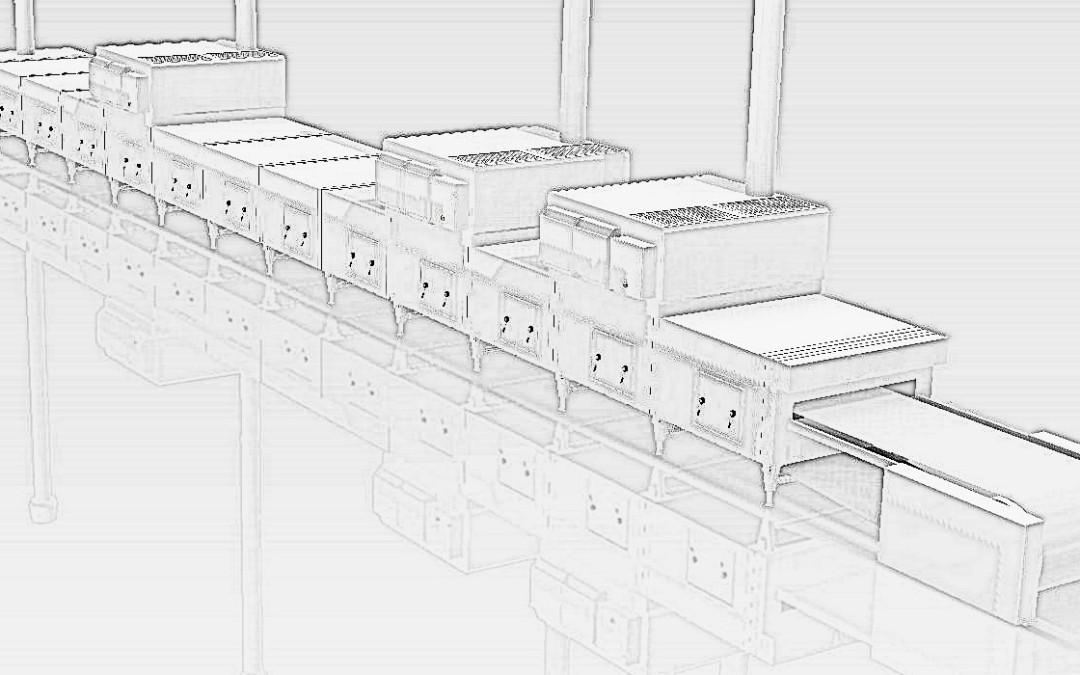

Having a modular industrial baking oven installed presents many advantages over the more traditional onsite build. When deciding the best route for your commercial bakery to take when having a new oven built the following facts should be part of that decision.

When a modular ovens is constructed there is less down time. Because of the fact that the majority of construction and manufacturing is done offsite and then put together in sections onsite, there is less need for plant operations to come to a halt. This savings on downtime automatically gives more production time and therefore can save a good amount of capital, equating to an overall lower cost for the total project.

In addition to the savings, there are added advantages to less time onsite. Due to less construction in the plant/bakery, there are lower chances for cross contamination as well as higher levels of overall dust control, resulting in less overall need for regulatory inspection.

Next because of the way a modular oven is constructed, it makes maintenance and repairs easier, allowing each section to be worked on individually without necessarily shutting down the entire line.

Finally, creating a modular oven build allows for easy expansion and/or contraction depending on the bakery’s needs in the future. This same ability makes transfer of the ovens from one facility to another, in case of a relocation, a much easier process.

With the needs of plants constantly changing and everybody looking for the most economical way to expand or simply keep the bakery running, a modular oven build would have to be an option for you to consider. To schedule a consultation with one of our knowledgeable staff, email us here or call us at 951-677-5274.

TDS Heat Solutions, Inc. is a manufacturer of industrial ovens and a distributor for some of the top brand names in the global industrial heating industry. Specialized in heat innovations, TDS is here to help you with any of your industrial heating needs.